- Home

- Coffee Valve Academy

- How Durable Are Degassing Valves? Do They Affect the Packaging Lifespan?

Usage & Installation

How Durable Are Degassing Valves? Do They Affect the Packaging Lifespan?

April 1, 2025

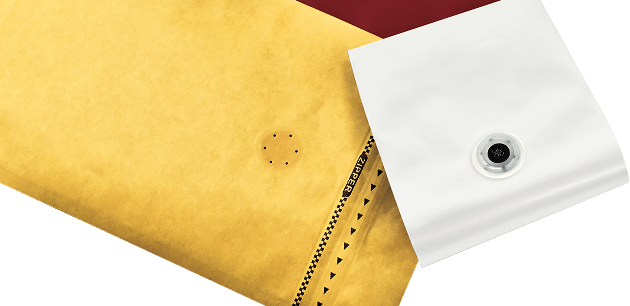

The durability of degassing valves plays a critical role in real-world applications, especially for packaging sensitive products such as food (e.g., coffee), fermented goods, or medical materials.

Key factors that determine the durability of degassing valves

Material selection

-

PP (Polypropylene) / PE (Polyethylene): Common in disposable food packaging, offering good heat resistance and chemical stability. Suitable for short- to medium-term storage.

-

Silicone membrane: Excellent elasticity and sealing performance. It can withstand repeated pressure changes without deformation, ideal for long-term storage or applications needing consistent vent control.

-

High-performance film materials: Some brands use microporous polymer membranes with excellent selective permeability and long-lasting durability.

Design structure

-

Mechanical valve designs (e.g., spring-type or micro-pressure control) offer more stable opening/closing cycles and longer lifespan.

-

Non-mechanical microporous designs focus on “zero mechanical failure,” suitable for environments with minimal pressure fluctuations.

Application conditions

-

The greater the fluctuations in temperature, humidity, and pressure, the higher the demands on valve structural stability.

-

In harsh conditions like high humidity or ocean shipping, selecting moisture-resistant materials and proper sealing is essential.

Do degassing valves affect overall packaging lifespan?

When the correct valve is selected, it can actually extend the packaging lifespan and product shelf life:

-

Prevents swelling or rupture (by releasing internal gases)

-

Blocks oxygen and moisture (maintains seal and quality)

-

Preserves product flavor and stability (e.g., coffee aroma, texture of fermented foods)

However, using the wrong material or poor installation may cause:

-

Valve degradation → failure to vent or seal properly

-

Structural deformation → oxygen ingress and product spoilage

-

Valve detachment → inability to maintain internal pressure over time

Best practices

-

Choose a valve lifespan that suits the product’s shelf life and logistics environment

-

Ensure compatibility with the bag material to prevent sealing issues

-

Select certified valve suppliers (e.g., FDA, SGS) for quality assurance

Conclusion:

The durability of degassing valves directly affects packaging performance and lifespan. With proper material selection and installation, degassing valves not only maintain functionality but also greatly enhance product stability and safety during storage, transport, and display.

-

Product & Technology

One-Way Degassing Valve

April 1, 2025

-

Product & Technology

What is a PE One-Way Degassing Valve?

May 29, 2022

-

Product & Technology

Is PE Recyclable?

April 1, 2025

-

Product & Technology

How Is a Degassing Valve Different from a Regular Vent Hole?

February 27, 2025

-

Market Demand & Innovation

Global One-Way Degassing Valve Market Continues to Grow, Driven Strongly by Coffee Industry

May 29, 2022

-

Usage & Installation

How Durable Are Degassing Valves? Do They Affect the Packaging Lifespan?

April 1, 2025