- Home

- Coffee Valve Academy

- How Is a One-Way Valve Different from a Regular Vent Hole?

Product & Technology

How Is a Degassing Valve Different from a Regular Vent Hole?

March 6, 2025

The One-Way Degassing Valve and the Regular Vent Hole are both devices used to regulate airflow, but they differ significantly in function, design, and application. Below is a breakdown of their key differences:

Function and Operating Principle

| Comparison | One-Way Degassing Valve | Regular Vent Hole |

|---|---|---|

| Airflow Direction | One-way (only releases gas from inside) | Two-way (allows free exchange of air) |

| Sealing | Prevents outside air, moisture, or contaminants | No sealing; air and moisture may enter |

| Main Function | Releases internal pressure to prevent package swelling or bursting | Keeps pressure balanced but may cause oxidation or spoilage |

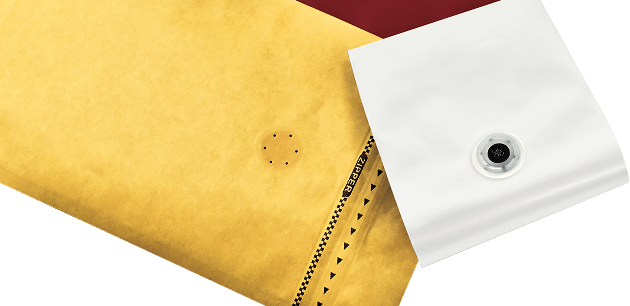

- Degassing valves typically use silicone membranes or microporous films that open under internal pressure and close to block external air or moisture.

- Vent holes are simply open holes without mechanisms to block air ingress.

Application Scenarios

| Application | One-Way Degassing Valve | Regular Vent Hole |

|---|---|---|

| Coffee Packaging | Releases CO₂ while preventing oxygen from entering, preserving freshness | Oxygen enters freely, accelerating oxidation and flavor loss |

| Fermented Foods (kimchi, cheese) | Releases fermentation gases, prevents swelling | Allows external contamination, affecting fermentation |

| Medical / Chemical Products | Maintains internal purity and prevents contamination | May compromise product stability |

| Precision Electronics | Regulates internal pressure, protects components | Risk of dust or moisture intrusion |

- One-way valves are ideal for gas-release applications where air ingress must be avoided (food, medical, chemical, electronics).

- Vent holes are better suited for equipment that only requires basic airflow (e.g., ventilation in machinery).

Performance Comparison

| Feature | One-Way Degassing Valve | Regular Vent Hole |

|---|---|---|

| Prevents Oxidation? | Yes — blocks oxygen | No — air flows freely |

| Water/Dust Protection? | Yes — resists moisture/dust | No — vulnerable to environment |

| Pressure Regulation? | Yes — releases internal gas | Yes — but with contamination risk |

- Choose one-way valves for freshness-critical products like food or chemicals.

- Use regular vent holes when airflow matters more than protection.

Conclusion

How to Choose Between Them?

- Use One-Way Degassing Valves when gas must be released without letting air/moisture in (e.g., coffee, fermented goods, medical supplies).

- Use Regular Vent Holes when basic ventilation is sufficient (e.g., machinery, devices).

In short, degassing valves are better for:

- Preventing oxidation, contamination, and moisture damage

- Maintaining seal integrity while managing internal pressure

Choose based on your product’s gas-release needs, sensitivity, and protection requirements!

-

Product & Technology

One-Way Degassing Valve

April 1, 2025

-

Product & Technology

What is a PE One-Way Degassing Valve?

May 29, 2022

-

Product & Technology

Is PE Recyclable?

April 1, 2025

-

Product & Technology

How Is a Degassing Valve Different from a Regular Vent Hole?

February 27, 2025

-

Market Demand & Innovation

Global One-Way Degassing Valve Market Continues to Grow, Driven Strongly by Coffee Industry

May 29, 2022

-

Usage & Installation

How Durable Are Degassing Valves? Do They Affect the Packaging Lifespan?

April 1, 2025